Summary

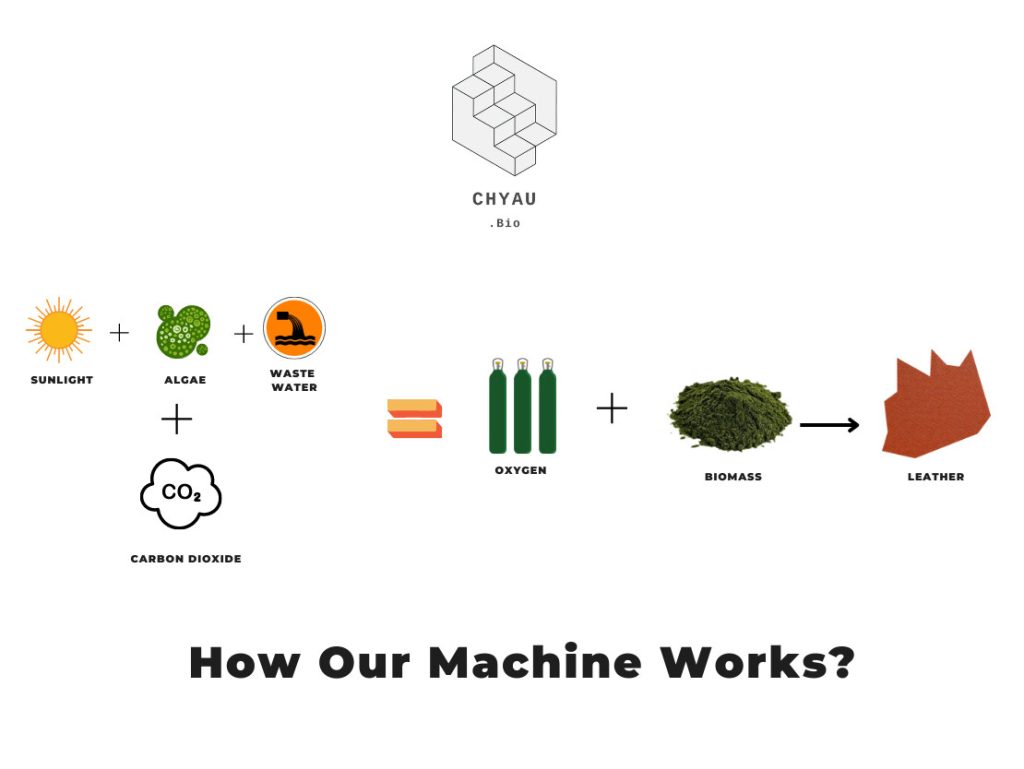

Urban areas in Nepal, and beyond in the Hindu Kush Himalaya, are facing grave and growing environmental challenges in terms of air pollution, the piling up of waste, and climate change. However, technologies are now available that can address these problems simultaneously. An algae bioreactor is a machine that utilises carbon dioxide, wastewater, and algae to produce biomass and oxygen. Thereby it helps trap air, water, and solid waste pollution. Just two algae bioreactors, installed in Pulchowk and Jawalakhel in Kathmandu, have so far produced more than 12,000 litres of oxygen. Currently, efforts at scaling up are ongoing, both via laboratory tests and in conversation with the relevant municipal authorities.

Urban environments are facing multiple environmental challenges in terms of air pollution, waste management, and also the growing effects of climate change arising from rising levels of carbon dioxide in the atmosphere. Addressing these need a range of measures in different sectors. A certain level of mitigation can also be achieved by affordable technological solutions that are part of the way forward.

The problem

Over the last two decades, the growing number of motor vehicles, rising population due to migration, and greater waste generation have given rise to a range of environmental challenges in Nepal’s capital, Kathmandu. The air is more polluted, the water table more toxic, and solid waste is piling up at dumpsites. All this is adversely affecting the quality of daily life of the city’s residents. It can also affect the water cycle, and harm wildlife and biodiversity.

The solution

We are trying to address these crises simultaneously via the installation of algae bioreactors at multiple sites, Pulchowk and Jawalakhel in Kathmandu. An algae bioreactor is a machine that utilises photosynthesis, carbon dioxide (CO2), wastewater, and algae to produce biomass and oxygen. It uses the flue gas emissions from industries, factories, boilers, hospitals, waste incinerators, and any chimney to trap the CO2 in the algal biomass. The nutrients required for the algae to grow come from wastewater. Thus, it helps trapping air, water, and solid waste pollution within the system, and in the process helps in the mitigation of climate change.

The method

First, we study the wastewater quality and assess its negative impacts on the water bodies to determine the required technology and size in accordance with the budget of the client. Based on our research, we offer our clients a variety of wastewater treatment system options which they select based on the requirements. We also inform them about the cost of system maintenance. For example, a Fecal sludge treatment plant (FSTP) or Effluent Treatment Plant (ETP) would require minimal maintenance costs to operate in the long run.

Implementation

We tested this solution in a series of steps:

• In Phase 1, we tested whether the algae bioreactor would trap air pollutants

• In Phase 2, we tested the use of wastewater as a nutrient for the algae

• In Phase 3, we are currently testing the use of solid waste incineration gas as a source of CO2 for algal growth.

We have found that the algae bioreactor traps and converts air pollutants, wastewater, and solid waste into oxygen. It is a highly useful innovation, providing a sustainable method of waste management.

Healthy results

Until now, the algae bioreactors in Pulchowk and Jawalakhel in Kathmandu have produced more than 12,000 litres of oxygen. This has been achieved through the installation of a machine in a coverage area of less than 35 sq. ft . Producing that equivalent volume of oxygen would require a great number of trees over a large area. Besides oxygen, another by-product of the bioreactor is biomass. Hence, this solution is self-sufficient and has a huge potential to contribute to a circular economy. Currently, tests for scaling up are ongoing at Impact Hub Fab Lab in Kathmandu , where the algae bioreactor has been connected to a plastic recycling facility. We have also held discussions with municipalities regarding waste incineration facilities and the use of these machines, for which physical trials are to be conducted.

Contact

Gunjan Ghimire

Chyau Bio Technologies Pvt. Ltd.

Email: echo.ghimire@gmail.com and bio.chyau@gmail.com

Contact: +977-9742894429

SDG linkages

Each of the RMS solutions are linked to the 2030 Sustainable Development Goals outlined by the UN in 2015. The SDGs that this intervention contributes to are as follows: